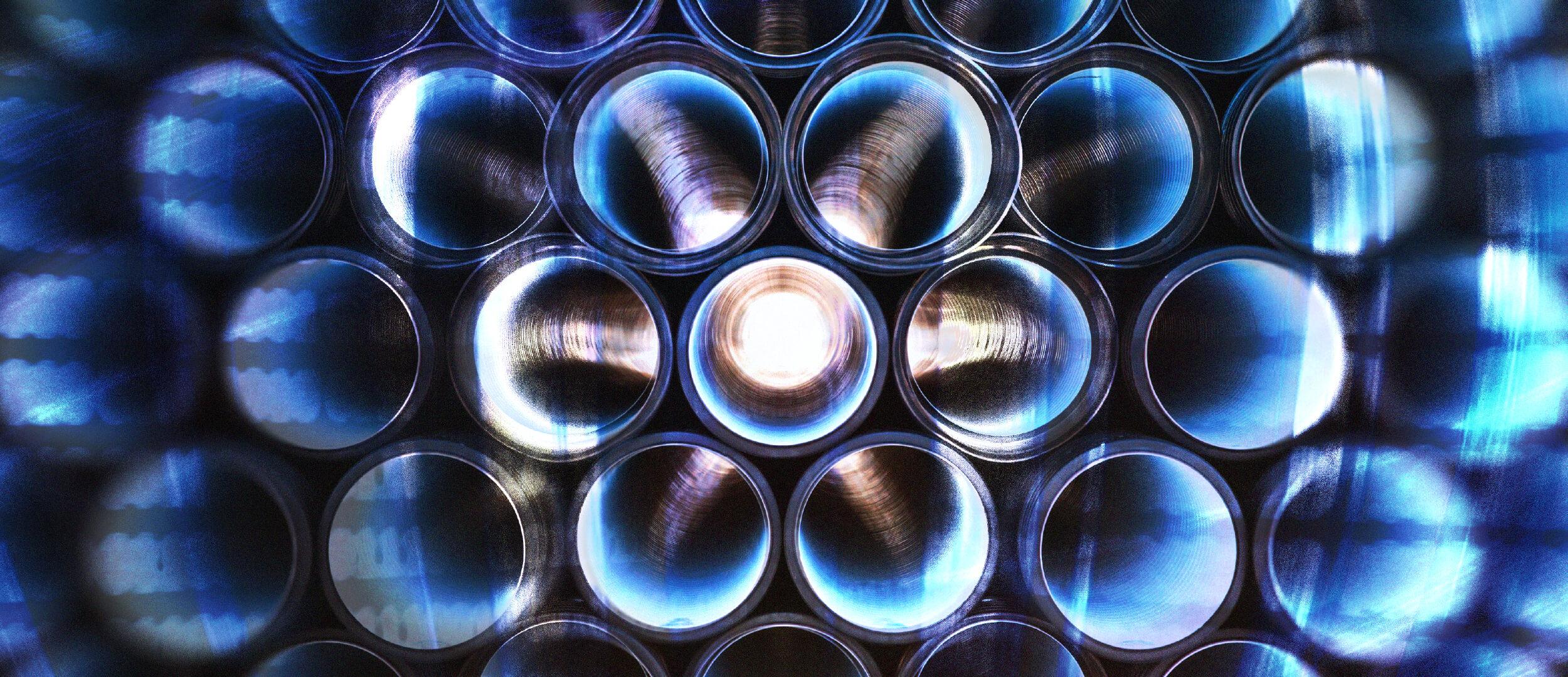

Manufacturing

Our tools and services drive agility and resilience in data-rich manufacturing environments, including engineering and automative.

Tech-enabled transformation in Manufacturing.

Decarbonisation & ESG

Enable data collection and reporting for ESG, to inform solutions and improvements. For example, predicting supply variation.

Customer Service.

Operational & Asset Intelligence.

Production Quality Control.

Engineering Knowledge Management.

Smart Manufacturing & Automation.

Discover how we use digital, data and AI

to accelerate success in Manufacturing.

%

Delivering 330% ROl to a major manufacturer through Al search.

Talk to us about driving your business forward with data.

We're here to help, whether you want a quick chat or a personalised demo from one of our experts. Just fill in the form and we'll be in touch within one working day.